Welcome to Geotech!

Optimizing Exploration ROI with 0.05nT Sensitivity 丨Proton Magnetometer

TIPS:Every drilling miss costs $50,000 or more. A high-sensitivity magnetometer changes the economics of exploration. This guide reveals how 0.05nT precision reduces false positives. Geotech’s proton magnetometer series enables data-driven targeting decisions. Learn how high-sensitivity magnetometer surveys improve hit rates by 40%. Discover why professional teams choose our proton magnetometer for critical mineral and archaeology projects.

Ⅰ. The Cost of Guesswork in Geophysical Surveying

Exploration projects bleed money on unnecessary drilling. Each borehole costs $30,000 to $150,000. False positives from low-resolution data drive these expenses. Teams need precision targeting. They need geomagnetic survey equipment that eliminates uncertainty.

Traditional magnetometers detect anomalies. They cannot resolve subtle features. Standard sensors miss weak signals. They blend adjacent targets. The result: ambiguous data that forces conservative drilling patterns. This approach wastes capital. It extends project timelines.

High-sensitivity magnetometer technology transforms this equation. Geotech’s instruments detect 0.05nT variations. This precision reveals hidden structures. It distinguishes ore bodies from background noise. It pays for itself through reduced drilling.

Ⅱ. Sensitivity Metrics: What 0.05nT Means in Practice

1. Understanding the Scale

Earth’s magnetic field measures 50,000nT. A proton magnetometer with 0.05nT resolution detects one part in one million variations. This sensitivity matches laboratory-grade SQUID systems. It exceeds standard field instruments by 10x.

Consider the implications. A small iron ore body at 50 meters depth creates a 2nT surface anomaly. A 0.05nT high-sensitivity magnetometer resolves this clearly. Standard 0.5nT instruments barely register it. The difference determines discovery versus oversight.

2. Signal-to-Noise Engineering

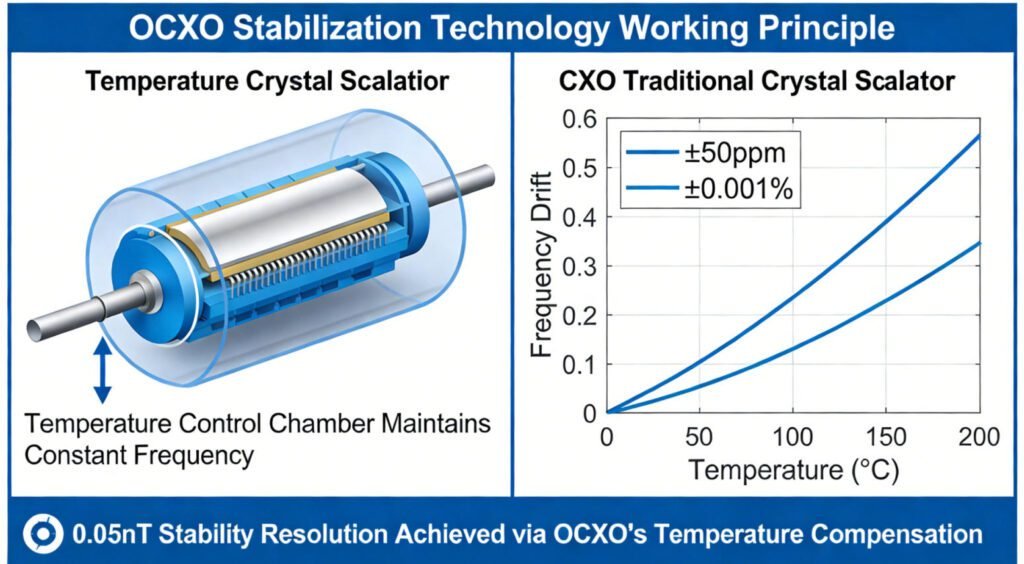

Raw sensitivity means nothing without stability. Temperature changes cause drift. Electronic noise masks weak signals. Geotech integrates OCXO magnetometer stabilization to solve these problems.

Our oven-controlled crystal oscillators maintain constant frequency. They eliminate temperature-induced drift. They provide reference stability to 0.001%. This allows true 0.05nT resolution in field conditions. Not just laboratory promises. Real-world performance.

3. Gradient Tolerance

Mineralized zones create strong magnetic gradients. These can confuse standard sensors. Geotech’s portable magnetic gradiometer configuration handles 8,000nT/m gradients. Dual-sensor arrays cancel common-mode noise. They enhance anomaly contrast.

This capability matters in complex geology. Iron formations generate steep gradients. Remnant magnetization distorts fields. High-tolerance systems maintain accuracy where others fail.

Ⅲ. Five Survey Strategies for Maximum ROI

1. High-Density Grid Mapping

Standard surveys use 50-meter line spacing. This resolution misses narrow ore shoots. High-sensitivity magnetometer surveys can tighten spacing to 10 meters. They maintain reasonable acquisition speed.

The economic trade-off favors precision. Doubling survey density adds 30% to field costs. It reduces drilling by 50% through better targeting. Net project savings often exceed $200,000.

2. Time-Lapse Monitoring

Ore bodies change. Oxidation alters magnetic signatures. Groundwater affects conductivity. Fixed-base geomagnetic survey equipment monitors these variations.

Geotech’s base station mode samples every 2 seconds. It tracks diurnal corrections automatically. This enables long-term stability studies. It detects subtle environmental changes. It supports environmental compliance monitoring.

3. Gradient Array Configuration

Single-point measurements show total field strength. Gradient measurements reveal source geometry. Portable magnetic gradiometer surveys map vertical and horizontal derivatives.

This technique locates pipeline edges precisely. It resolves archaeological feature boundaries. It distinguishes near-surface clutter from deep targets. Gradient data requires no regional corrections. It simplifies interpretation.

4. Walking-Mode Acquisition

Stop-and-go surveying limits productivity. Geotech’s walking-mode proton magnetometer acquires data continuously. Operators move at 3-5 km/h. Systems sample every 3 seconds.

This approach covers 20 kilometers per day. It matches the efficiency of airborne surveys. It delivers ground-level resolution. It suits reconnaissance mapping and detail work alike.

5. Multi-Sensor Integration

Magnetic data alone rarely suffices. Combine high-sensitivity magnetometer surveys with electrical methods. Use induced polarization for sulfide detection. Add electromagnetic profiling for conductivity.

Geotech instruments export data in standard formats. They integrate with GIS platforms. They support joint inversion workflows. Multi-physics approaches reduce ambiguity. They improve confidence in drill targeting.

Ⅳ. Application-Specific Workflows

1. Mineral Exploration

Iron ore bodies produce strong magnetic responses. But subtle variations indicate grade changes. Gold deposits often show weak anomalies. Base metals require precise gradient mapping.

Geotech’s JPMG series achieves ±0.1nT absolute accuracy. This enables quantitative interpretation. Amplitude analysis estimates ore volume. Gradient modeling constrains depth. Results guide drill programs with confidence.

2. Archaeological Survey

Buried walls and kilns create subtle anomalies. Often less than 1nT. Standard instruments miss these features. High-sensitivity magnetometer mapping reveals settlement patterns non-destructively.

Walking-mode acquisition covers large sites quickly. 0.05nT resolution detects hearths and ditches. GPS integration provides centimeter positioning. Data guides excavation planning. It preserves site integrity.

3. Underground Pipeline Detection

Urban construction risks pipeline strikes. Magnetic anomaly detection locates ferrous pipes without excavation. Gradient measurements determine burial depth. They distinguish parallel utilities.

Geotech systems operate in congested environments. They filter electrical interference. They provide real-time positioning. Results integrate with CAD systems for construction planning.

4. Environmental and Geohazard Studies

Landslides disturb magnetic mineral alignments. Contamination alters soil susceptibility. Long-term monitoring detects these changes.

Base station installations track volcanic precursors. They monitor earthquake-related electromagnetic signals. OCXO magnetometer stability ensures meaningful trend detection.

Ⅴ. Technical Implementation Guide

1. Site Preparation

Clear vegetation from survey lines. Mark grids with GPS precision. Install base stations on stable ground. Avoid ferrous objects within 10 meters. These steps ensure clean data acquisition.

2. Instrument Calibration

Verify proton magnetometer performance daily. Check sensor tuning. Confirm GPS lock. Test data download links. Document environmental conditions. Systematic procedures maintain data quality.

3. Data Acquisition Protocols

Maintain consistent sensor height. Walk at steady pace in walking mode. Record unusual conditions. Flag suspect readings immediately. Good field practice prevents costly re-surveys.

4. Quality Control

Check internal consistency. Monitor diurnal drift. Verify gradient tolerances. Compare with known benchmarks. Apply statistical filters carefully. Preserve original data always.

Ⅵ. The Geotech JPMG Series Advantage

Our instruments integrate 0.05nT resolution with field-proven reliability. Key specifications include:

- Sensitivity: 0.01nT resolution, 0.05nT noise floor

- Accuracy: ±0.1nT absolute, ±0.05nT relative

- Stability: OCXO temperature control, <0.001% drift

- Speed: 3-second sampling, walking-mode capable

- Range: 20,000-120,000nT, 8,000nT/m gradient tolerance

Options include single-sensor magnetometer and dual-sensor portable magnetic gradiometer configurations. GPS integration provides real-time positioning. Internal storage holds 2 million readings. USB and RS-232 interfaces enable rapid data transfer.

Software generates contour maps and 3D profiles. It exports to industry-standard formats. It supports inversion modeling. Complete workflow integration minimizes processing time.

Ⅶ. Economic Impact Analysis

Consider a typical mineral exploration program. Standard magnetometry identifies 20 targets. Drilling tests all 20. Five prove economic. Hit rate: 25%.

High-sensitivity magnetometer surveys resolve subtle features. They rank targets by confidence. Teams drill 12 high-priority anomalies. Five prove economic. Hit rate: 42%. Same discoveries. Eight fewer drill holes. Savings: $300,000 to $1,200,000.

The instrument pays for itself in one project. Accuracy improvements compound across program life. Data quality supports resource estimation. It reduces technical risk. It attracts investment.

Ⅷ. Future Trends and Developments

Quantum sensors promise femtotesla sensitivity. MEMS devices may enable drone deployment. Artificial intelligence automates anomaly detection. These advances will expand capabilities.

However, proven proton magnetometer technology remains the workhorse. It balances sensitivity, reliability, and cost. It operates without cryogenic cooling. It functions in harsh environments. For most applications, it delivers optimal ROI.

Geotech continues refining our platforms. We enhance integration. We improve user interfaces. We maintain our commitment to precision and durability. Our instruments evolve with industry needs.

Ⅸ. Conclusion

Exploration success depends on data quality. High-sensitivity magnetometer technology transforms ambiguous anomalies into actionable targets. Geotech’s 0.05nT resolution enables precise decision-making. It reduces drilling risk. It accelerates project timelines.

Choose instruments that deliver proven performance. Invest in geomagnetic survey equipment that pays returns through accuracy. Contact Geotech to discuss your specific survey requirements. Discover how precision magnetometry improves your exploration economics.

Reference

- WIKI:https://en.wikipedia.org/wiki/Electrical_resistivity_tomography

- Society of Exploration Geophysicists (SEG) https://seg.org/

- Society of Environmental and Engineering Geophysicists (EEGS) https://www.eegs.org/

- Geology and Equipment Branch of China Mining Association http://www.chinamining.org.cn/

- International Union of Geological Sciences (IUGS) http://www.iugs.org/

- European Geological Survey Union (Eurogeosurveys) https://www.eurogeosurveys.org/

-1.png)