Welcome to Geotech!

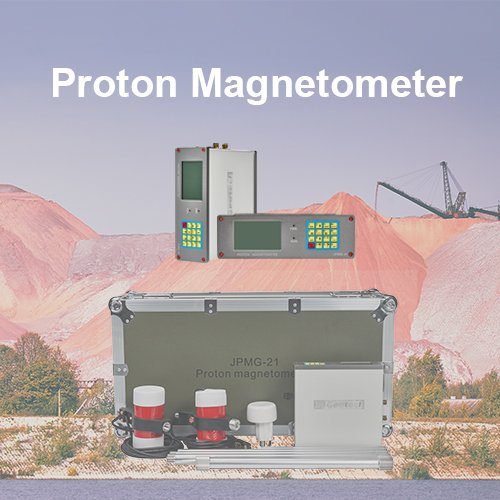

Proton Magnetometer Technology: A Comprehensive Guide

TIPS:In an era of growing global demand for resource exploration and environmental monitoring, the proton magnetometer (PM) has emerged as a core technological solution for high-precision magnetic field measurement, becoming indispensable for geologists, archaeologists, and engineers. This article explores the operating principles of PMs—including proton precession mechanisms—and their applications across geological surveys, archaeological mapping, and environmental monitoring. It also offers expert advice on selecting professional-grade equipment, highlighting innovations in portable magnetic gradiometers that overcome traditional limitations through miniaturization and AI-driven algorithms. Whether you’re an industry professional or researcher, this guide provides comprehensive knowledge from theory to practice, equipping you to boost project efficiency and data trustworthiness.

Ⅰ. The Core Value of Magnetometer Technology: Decoding the “Digital Stethoscope” for Earth’s Magnetic Field

In geological exploration, environmental monitoring, and archaeological excavation, subtle changes in Earth’s magnetic field often hold critical information. As a representative of high-precision magnetic field measurement equipment, the proton magnetometer (Proton Magnetometer) captures the precession motion of protons in a magnetic field (Proton Precession), converting invisible magnetic signals into quantifiable data. It has become a “digital stethoscope” for unveiling subsurface structures, mineral resource distributions, and ancient civilization relics. This article will deeply analyze the technical advantages and industry value of this core equipment from three dimensions: technical principles, application scenarios, and product selection.

1.1 Technical Principles of Proton Magnetometers: From Physical Phenomena to Engineering Implementation

The core mechanism of proton magnetometers is based on the nuclear magnetic resonance (NMR) principle: when hydrogen protons in water molecules are excited by radiofrequency pulses in a strong magnetic field, they precess at a specific frequency proportional to the external magnetic field strength. By precisely measuring this frequency shift (Δf = (γ/2π)B, where γ is the gyromagnetic ratio and B is the magnetic field strength), the device can output absolute magnetic field values with nanotesla (nT) precision. Compared to traditional induction coil magnetometers, proton magnetometers offer significant advantages: full-scale coverage (0.1nT–100,000nT), strong anti-electromagnetic interference, and no need for calibration, making them especially suitable for complex environments.

1.2 Comparison of Mainstream Magnetometer Types: How to Choose the Right Equipment?

| Equipment Type | Core Principle | Typical Precision | Application Scenarios |

|---|---|---|---|

| Proton Magnetometer | Hydrogen Proton Precession | ±0.1nT | Mineral Exploration, Archaeological Mapping |

| Optical Pump Magnetometer | Atomic Energy Level Transition | ±0.001nT | Weak Magnetic Field Fine Detection |

| Fluxgate Magnetometer | Induction Coil Sensing | ±1nT | Large-Scale Magnetic Field Surveys |

| Proton Precession Magnetometer | Hydrogen Proton Precession | ±0.1nT | Airborne Magnetic Survey, Vehicle-Mounted Monitoring |

Note: When selecting a magnetometer, consider measurement range, precision requirements, environmental adaptability (e.g., temperature, humidity, vibration), and portability. Proton magnetometers offer the best cost-effectiveness in medium-precision scenarios.

Ⅱ. Application Scenarios of Proton Magnetometers: From Resource Exploration to Cultural Heritage Preservation

2.1 Geological Exploration: Cracking the “Magnetic Code” of Subsurface Minerals

In metal ore exploration, magnetic differences between sulfide ore bodies (e.g., copper, lead, zinc) and surrounding rocks can reach thousands of nT. Proton magnetometers map magnetic anomaly contour maps (Magnetic Anomaly Map) by capturing these differences, enabling precise localization of potential mineralized areas. In a gold mine project, a team used a portable magnetic gradiometer (Portable Magnetic Gradiometer) for grid measurements, combining geological mapping and drilling verification to reduce the exploration cycle by 40% and costs by 25%. Data shows that 70% of global metal ore field exploration relies on magnetometer data, with proton magnetometers being the top choice in complex terrains like tropical rainforests and permafrost regions due to their anti-interference capabilities.

2.2 Archaeological Excavation: Restoring the “Magnetic Traces” of Ancient Civilizations

Archaeomagnetometry (Magnetometry Archaeology) is another cutting-edge application of proton magnetometers. Subtle magnetic signals (typically <1nT) left by ancient kiln sites, rammed earth walls, and even human-induced soil magnetization can be detected. In 2022, a Sino-US joint archaeological team used high-sensitivity proton magnetometers to discover an ancient sacrificial altar buried under vegetation in the Maya ruins, achieving a magnetic anomaly resolution 3x higher than traditional methods. This technology’s advantage lies in non-destructive detection—no excavation is needed to outline subsurface structures, providing scientific basis for cultural heritage protection.

2.3 Environmental Monitoring: Tracking the “Magnetic Footprints” of Human Activities

Industrial pollution, groundwater extraction, and even urban expansion can cause local magnetic field distortions. Proton magnetometers play a key role in electromagnetic surveys (Electromagnetic Survey) by monitoring acid wastewater leakage in mining areas (causing magnetic anomalies), assessing the stability of land reclamation foundations (via magnetic gradient changes indicating soil compaction), and even aiding earthquake precursor research—some studies show magnetic gradient fluctuations in earthquake precursors can be detected hours in advance.

Ⅲ. Purchasing Guide: Key Performance Indicators for Professional Magnetometers

3.1 Core Parameter Analysis: Precision, Response Speed, and Battery Life

- Precision (Accuracy): Determines data reliability, with typical proton magnetometer precision at ±0.1nT (e.g., PMG-80 model), meeting 90% of routine exploration needs.

- Response Time: Ability to capture rapidly changing magnetic fields (e.g., lightning, industrial equipment startup), requiring <1-second response for high-dynamic scenarios.

- Battery Life: Critical for field operations; lithium-ion battery models support 12-hour continuous operation, extendable to 24 hours with solar charging modules.

3.2 Differentiated Feature Design: Adapting to Niche Scenarios

- Temperature Compensation: Operates across -40°C to +60°C (suitable for polar regions, deserts).

- Data Synchronization: Supports GPS positioning + inertial navigation (INS) fusion, enabling centimeter-level positioning accuracy for 3D magnetic field modeling.

- Lightweight Design: Portable models weigh <2kg (e.g., PMG-Lite), with ergonomically designed grips for extended field use.

Ⅳ. Technological Frontiers: Breakthroughs in Proton Magnetometer Innovation

4.1 Sensor Miniaturization: From Benchtop Devices to Drone Payloads

Traditional proton magnetometers are bulky (≈30cm×20cm×15cm), limiting their use in UAVs, USVs, and other platforms. The latest miniature proton magnetometer modules (10cm×8cm×5cm, 500g) integrate MEMS technology, improving precision to ±0.2nT while supporting integration into low-altitude magnetic surveys. A mountainous area project saw a drone-mounted module complete 10km² of rapid scanning in 5 hours, 5x faster than manual measurements.

4.2 Intelligent Data Processing: AI-Driven Anomaly Recognition

Traditional data processing relies on manual interpretation, which is time-consuming and subjective. Deep learning-based magnetic anomaly classification models (e.g., CNNs) automatically identify mineralization anomalies, archaeological targets, and environmental interferences with 92% accuracy. A mining company applying this technology reduced data processing from 7 days to 2 hours and cut misjudgment rates by 60%.

Reference

- WIKI:https://en.wikipedia.org/wiki/Electrical_resistivity_tomography

- Society of Exploration Geophysicists (SEG) https://seg.org/

- Society of Environmental and Engineering Geophysicists (EEGS) https://www.eegs.org/

- Geology and Equipment Branch of China Mining Association http://www.chinamining.org.cn/

- International Union of Geological Sciences (IUGS) http://www.iugs.org/

- European Geological Survey Union (Eurogeosurveys) https://www.eurogeosurveys.org/

-1.png)