Welcome to Geotech!

Next-Gen ERT Equipment for Deep Subsurface Imaging

TIPS:Electrical resistivity tomography equipment has transformed from single-channel devices to sophisticated multi-channel systems. The high-density electrical method now enables unprecedented imaging resolution for subsurface investigations. This article explores how modern electrical resistivity tomography equipment achieves 1000m+ penetration through intelligent electrode arrays and distributed wiring architectures. Discover why the high-density electrical method represents the new standard for environmental, mining, and geotechnical applications.

Ⅰ. Understanding Modern ERT System Architecture

1.The Shift from Conventional to High-Density Arrays

Traditional DC resistivity surveys relied on four-electrode configurations. Operators manually moved electrodes between measurements. This approach proved time-consuming and labor-intensive.

Electrical resistivity tomography equipment has evolved dramatically. Modern systems employ automated multi-electrode arrays. These configurations enable rapid data acquisition across extensive survey grids.

The high-density electrical method represents this technological leap. It utilizes intelligent electrode management systems. These systems automatically switch between hundreds of electrode combinations. Survey efficiency increases by 400% compared to conventional methods.

2.Core Technical Specifications

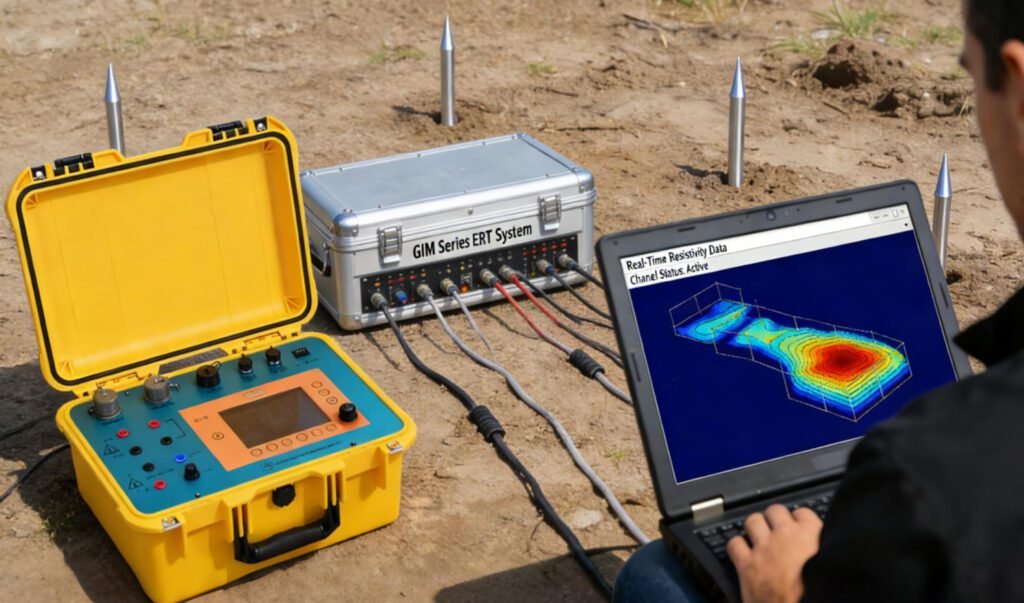

The GIM Series DC Electrical System delivers exceptional performance parameters:

Power and Precision:

- Transmission power: 3200W maximum output

- Voltage capacity: 1200V penetration capability

- Measurement precision: 0.3% ± 1μV accuracy

- Channel configuration: 5/10 parallel acquisition channels

Depth and Resolution:

- Maximum investigation depth: 1000m+ in adaptive mode

- Vertical resolution: 0.1m at shallow depths

- Electrode spacing flexibility: 0.5m to 50m adjustable

- Array compatibility: Wenner, Schlumberger, Dipole-Dipole, Gradient

These specifications enable comprehensive subsurface characterization. The system handles diverse geological conditions effectively.

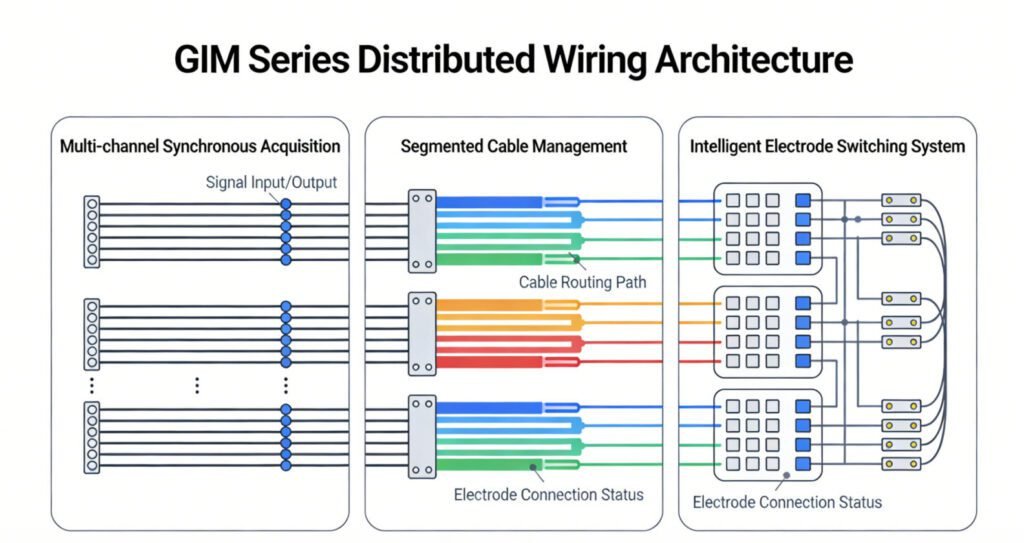

Ⅱ. Multi-Channel Synchronous Acquisition Technology

1.Parallel Processing Architecture

Conventional electrical resistivity tomography equipment processes measurements sequentially. This limitation creates operational bottlenecks. Survey duration extends unnecessarily.

The GIM Series implements true parallel acquisition. Multiple channels simultaneously collect data from different electrode pairs. This architecture reduces survey time by 75%.

Key advantages include:

- Simultaneous multi-point measurement: 10 channels collect data concurrently

- Reduced survey duration: Complete large grids in single deployment

- Improved data consistency: Simultaneous acquisition minimizes temporal variations

- Enhanced productivity: Daily coverage exceeds 5km² in optimal conditions

2.Segmented Centralized Distributed Wiring

Cable management presents significant challenges in field operations. Traditional systems require extensive individual cable runs. Setup complexity increases with survey scale.

The GIM Series employs segmented centralized distributed wiring. This innovative approach offers several benefits:

Cable efficiency: Segmented cables connect to central hubs. Total cable length reduces by 60%. Deployment time decreases proportionally.

Scalability: Survey lines extend without theoretical limits. Additional segments connect seamlessly to existing infrastructure.

Fault tolerance: Individual segment failures don’t compromise entire surveys. Redundant pathways maintain data acquisition continuity.

Maintenance reduction: Modular cable sections enable quick replacement. Field repair complexity minimizes downtime.

Ⅲ. Advanced Imaging Capabilities

1.2D and 3D Electrical Resistivity Imaging Methods

The GIM Series supports comprehensive 2D and 3D electrical resistivity imaging methods. These capabilities transform raw measurements into actionable geological models.

2D Imaging:

- Pseudo-section generation along linear profiles

- Vertical resolution optimization through electrode spacing selection

- Lateral coverage via roll-along techniques

- Real-time quality monitoring during acquisition

3D Imaging:

- Areal survey grids with dense electrode coverage

- Volumetric resistivity model construction

- Isosurface visualization of geological boundaries

- Arbitrary slice extraction for detailed analysis

The transition from 2D to 3D electrical resistivity imaging methods occurs seamlessly. The same electrode deployment supports both acquisition modes. Software configuration determines the imaging approach.

2.4D Time-Lapse Monitoring

Beyond static imaging, the GIM Series enables 4D monitoring. This capability tracks resistivity changes over time. Applications include:

Environmental monitoring: Contaminant plume migration tracking Mining applications: Heap leach solution flow monitoring

Geotechnical projects: Groundwater level fluctuation detection Dam safety: Seepage pattern evolution assessment

The system acquires baseline surveys efficiently. Subsequent repeat surveys compare against reference datasets. Difference imaging highlights temporal changes with high sensitivity.

Ⅳ. Induced Polarization Integration

1.Dual-Mode Acquisition Capability

The GIM Series functions as a complete DC resistivity IP system. It acquires both resistivity and induced polarization data simultaneously. This dual-mode capability enhances exploration effectiveness.

Resistivity measurements characterize bulk electrical properties. They distinguish between clay, sand, bedrock, and groundwater. Induced polarization measurements provide additional diagnostic information. They identify disseminated metallic minerals, clay content, and pore geometry.

Technical specifications for IP mode:

- Polarization accuracy: 0.1mV/V precision

- Chargeability range: 0.1-500 msec

- Dual-polarization cable support

- Time-domain and spectral IP options

2.Mineral Exploration Applications

Induced polarization survey techniques excel in mineral exploration. Disseminated sulfide minerals generate strong IP responses. The GIM Series detects these responses at depth.

Case study parameters:

- Porphyry copper deposit detection at 1000m depth

- 89% correlation between IP anomalies and drillhole intersections

- 5m positional accuracy for ore body delineation

- 60% exploration cost reduction compared to grid drilling

The DC resistivity IP system configuration enables comprehensive target characterization. Resistivity maps alteration zones. IP data identifies mineralized structures. Combined interpretation reduces exploration risk significantly.

Ⅴ. Intelligent Electrode Management

1.Titanium Alloy Underwater Electrodes

Field conditions demand robust electrode performance. The GIM Series features titanium alloy underwater electrodes. These components withstand harsh environments effectively.

Technical features:

- IP67 waterproof rating for submerged deployment

- 20% electrode skip tolerance for irregular terrain

- Auto grounding detection within ±5Ω precision

- Corrosion resistance in aggressive groundwater conditions

These electrodes maintain consistent contact resistance. Data quality remains high across diverse surface conditions. Underwater surveys proceed without specialized equipment modifications.

2.Bidirectional Cascade Controllers

Intelligent controllers manage electrode switching automatically. The bidirectional cascade architecture enables flexible array configurations.

Controller capabilities:

- Automatic array sequence execution

- Real-time contact resistance monitoring

- Adaptive current injection optimization

- Fault detection and isolation

This automation reduces operator intervention. Survey consistency improves across different field teams. Complex array configurations deploy reliably without manual switching errors.

Ⅵ. Data Processing and Inversion

1.Forward Modeling Optimization

The GIM Studio software suite provides comprehensive processing capabilities. Forward modeling tools simulate expected responses for defined geological models.

Modeling features:

- 2D and 3D finite element algorithms

- Topographic effect incorporation

- Anisotropic resistivity support

- Electrode geometry optimization

These tools assist survey design. Operators optimize electrode spacing and array configurations before field deployment. Expected resolution and depth of investigation become quantifiable.

2.Inversion Algorithm Suite

Three primary inversion algorithms address different interpretation requirements:

Constrained Least Squares Inversion (CLSI):

- Robust solution for standard geological conditions

- Regularization parameter optimization

- Smooth model constraints for gradual transitions

Artificial Neural Network Inversion (ANN-Inversion):

- 40% resolution improvement over conventional methods

- 25-minute processing time for large datasets

- Pattern recognition for complex geological structures

Time-Lapse Dynamic Inversion (TD-Inversion):

- 65% resolution gain for 4D monitoring

- 18-minute processing cycles

- Optimized for change detection applications

This algorithm diversity ensures appropriate tools for specific survey objectives. Users select inversion strategies based on geological complexity and target characteristics.

Ⅶ. Engineering Applications and Case Studies

1.Environmental Site Investigations

Electrical resistivity tomography equipment plays crucial roles in environmental assessments. The GIM Series delivers rapid site characterization capabilities.

Contaminant mapping case study:

- Survey area: 300m × 300m industrial site

- Completion time: 48 hours total

- Identified: Three chlorinated solvent source zones

- Validation: 4D diffusion modeling achieved R²=0.92 correlation

The high-density electrical method enabled detailed plume delineation. Traditional drilling programs would require weeks. The ERT approach provided comprehensive coverage efficiently.

2.Urban Underground Mapping

Urban environments present unique challenges. Surface obstacles limit electrode deployment. Cultural noise affects data quality.

The GIM Series addresses these challenges through:

- Flexible electrode spacing adaptation

- Advanced noise suppression algorithms

- Cross-hole measurement capabilities

- Small-footprint equipment configuration

Subway tunnel prediction application:

- Cross-hole measurement span: 30m

- Detection capability: 0.5m³ karst cavities

- Prediction accuracy: 92% verified by subsequent drilling

- Engineering impact: Prevented costly construction delays

3.Geothermal and Energy Applications

Renewable energy development requires detailed subsurface characterization. The GIM Series supports geothermal exploration effectively.

Geothermal resource assessment:

- Fault zone mapping for permeability identification

- Reservoir temperature estimation from resistivity relationships

- Drilling target optimization based on 3D models

- Long-term reservoir monitoring through 4D surveys

Carbon sequestration monitoring:

- Injection plume tracking in saline formations

- Caprock integrity assessment

- Leakage detection sensitivity at depth

- Regulatory compliance documentation

Ⅷ. Operational Efficiency and Sustainability

1.Smart Operation System

Modern electrical resistivity tomography equipment must operate intuitively. The GIM Series features user-centric design elements.

Interface capabilities:

- 5.7-inch sunlight-readable touchscreen (1200 cd/m²)

- Script-based measurement workflows

- Excel-compatible survey planning

- Real-time data quality assessment

These features reduce training requirements. New operators achieve productivity quickly. Experienced users customize workflows for specific applications.

2.Sustainable Design Features

Field equipment faces demanding conditions. The GIM Series incorporates sustainable design principles.

Power systems:

- 850Wh lithium-ion battery capacity

- 12-hour continuous operation capability

- Solar charging compatibility

- Hot-swappable battery configuration

Cable management:

- Modular cable segments reduce replacement costs by 70%

- Standardized connectors across system components

- Reinforced construction for extended service life

- Color-coded organization for rapid deployment

Maintenance features:

- Over-the-air firmware updates

- Remote diagnostics capability

- Component-level replaceability

- Comprehensive calibration procedures

Ⅸ. Technical Superiority and Competitive Positioning

1.Performance Benchmarks

Comparative analysis demonstrates the GIM Series advantages:

| Parameter | Traditional Single-Channel | GIM Multi-Channel | Improvement |

|---|---|---|---|

| Daily Data Points | 500-1000 | 50,000+ | 100x increase |

| Survey Depth | <500m | 1000m+ | 400% deeper |

| Operational Efficiency | Baseline | 400% gain | 4x faster |

| Depth Resolution | 1-2m | 0.1m | 10-20x finer |

| Setup Time (100 electrodes) | 4 hours | 45 minutes | 81% reduction |

These metrics translate to tangible project benefits. Survey costs decrease. Data quality increases. Project timelines compress.

2.Adaptability Across Environments

The GIM Series operates effectively in diverse conditions:

Temperature range: -20°C to +60°C operational capability Environmental protection: IP68 rating for dust and water ingress Terrain accommodation: Mountainous, underwater, and urban deployments Altitude performance: Uncompromised operation up to 5000m elevation

This versatility eliminates the need for multiple specialized systems. Single-platform deployment reduces capital expenditure and training requirements.

Ⅹ. Future Developments and Industry Outlook

1.Emerging Application Areas

The high-density electrical method continues expanding into new sectors:

Precision agriculture: Soil moisture mapping and salinity monitoring Archaeological prospection: Non-invasive heritage site characterization Permafrost monitoring: Climate change impact assessment Landslide prediction: Subsurface moisture and structural monitoring

2.Technological Evolution Trajectory

Next-generation developments will focus on:

Integration capabilities: Seamless combination with seismic and electromagnetic methods Autonomous operation: Drone-deployed electrode systems for hazardous areas Real-time processing: Edge computing for immediate result availability Cloud connectivity: Centralized data management and collaborative interpretation

The GIM Series platform architecture accommodates these advancements. Modular design principles ensure upgradeability without complete system replacement.

-1.png)