Welcome to Geotech!

PSK-2 CNC Logging System

PRODUCT PARAMETERS

- Standardization and modularization

- Downhole digitization and coding transmission of measurement signals

- Oversampling technology obtains the most formation information

- Small size of downhole probe tube, high pressure resistance

Description

Abstract

Abstract

PSK-2 CNC Logging System is a new generation of digital logging equipment developed with new concepts and technologies based on the successful experience of existing digital logging equipment at home and abroad, keeping up with the new trend of international small digital logging technology development. Compared with other similar products, this equipment has the following advantages:

● Multiple measurement parameters, suitable for applications in different industries

● Modular design, lightweight design, easy equipment transportation

● Simple operation and maintenance

● High reliability, ultra-long MTBF

The main reason for the system to achieve these advantages is that it absorbs the strengths of various companies in the product design process; fully considers the needs of various industries; and considers the competitiveness of products in the international market. PSK-2 CNC Logging System currently has more than 20 types of formation parameters that can be measured, covering the needs of users in various fields such as metal mines, coal fields, oil fields, radioactive mines, hydrology, etc. The product has a very high cost performance.

Working principle

Working principle

Well logging is a method of measuring geophysical parameters by using the electrochemical, conductive, acoustic, radioactive and other geophysical properties of rock formations. It is one of the applied geophysical methods (including gravity, magnetic, electric, seismic and nuclear).

Features & Benefits

Features & Benefits

● Standardization and modularization

PSK-2 CNC Logging System adopts the concept of standardization and modularization design in terms of hardware and software, downhole probes and surface equipment, signal measurement and signal transmission. The benefits of standardization and modularization are that the product has very good consistency, very good maintainability and very high reliability. It is very convenient to operate and maintain, and the universal accessory design can be matched with different probes to achieve application expansion in different industries.

● Downhole digitization and coding transmission of measurement signals

All signals output by downhole probes are sent to the surface after A/D conversion and cell and channel coding. Digital coding transmission of measurement signals greatly improves the anti-interference ability, and the system itself can also perform error correction to ensure the quality of signal transmission. The downhole probe communicates with the ground in two directions, ensuring that operations can be performed directly on the PC, and the hardware equipment is simple and reliable.

● Oversampling technology obtains the most formation information

The PSK-2 CNC Logging System uses oversampling to collect formation information. The oversampling amount increases as the logging speed decreases. Oversampling ensures the need for digital filtering, improving spatial resolution and identifying useful information.

●Small size of downhole probe tube, high pressure resistance

The downhole probe tubes of PSK-2 CNC Logging System are almost all of Φ40 and Φ50mm in outer diameter and 1000-1500mm in length. The probe tubes are mostly made of stainless steel. Water pressure resistance is 20-40MPa and temperature is 70-90℃. Special application requirements can meet higher requirements, with water pressure resistance up to 60MPa and temperature up to 120℃.

System Configuration

System Configuration

PSK-2 CNC Logging System consists of a ground integrated host, various probes, software and PC, winch and cables.

1. Ground integrated host

The function of the ground integrated host of PSK-2 CNC Logging System is to supply a standard power supply (200V) to the downhole probe and to communicate with the downhole probe in two directions. The communication signal is a digital signal that is encoded and can perform forward error correction. The working state and opening of the downhole probe are controlled by downward instructions. The parameters measured by the downhole probe are transmitted to the integrated host, and after demodulation and processing, they are sent to the PC for further data processing and saving the result data. The communication interface between the integrated host and the PC is USB1.0 or USB2.0, and the user can also choose RS232 mode. The integrated host works in a multi-tasking mode, and multiple MCUs are integrated to complete fault self-detection, power supply protection, modulation and demodulation, and depth measurement, ensuring smooth oversampling and very strong real-time performance.

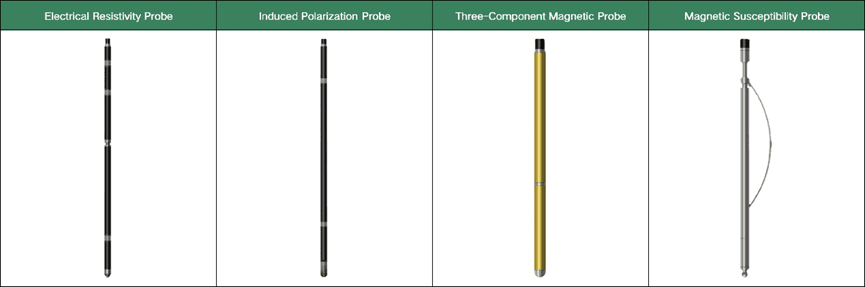

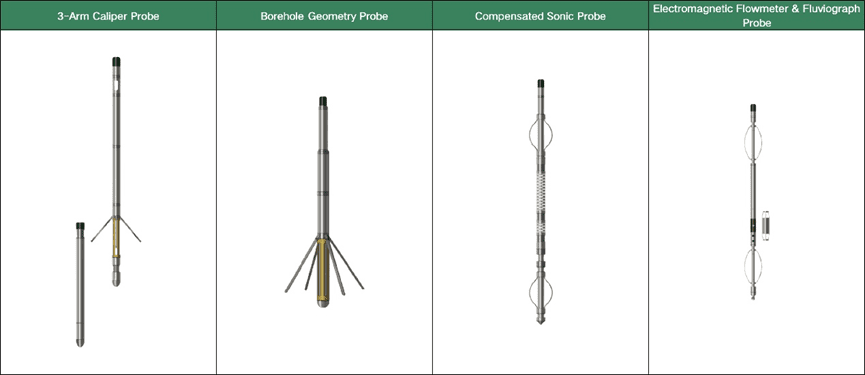

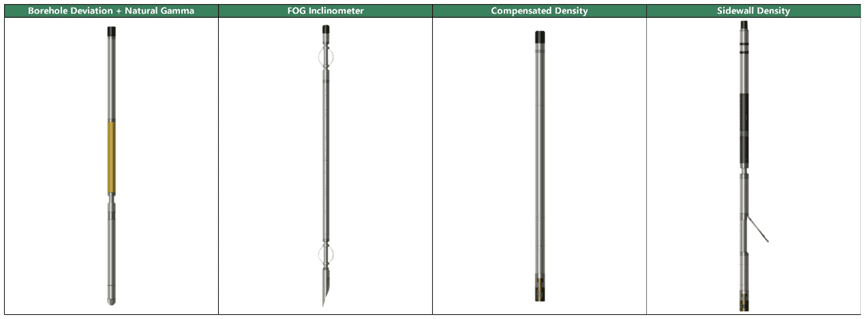

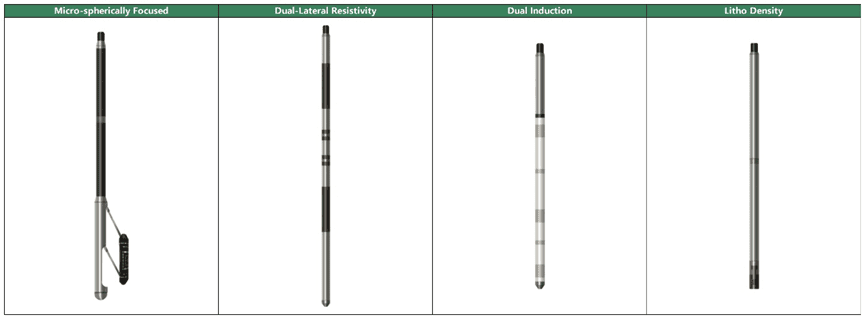

2. Probes

Each single-parameter or combined-parameter probe consists of a standard power module, a modulation and demodulation module, and its own measurement and processing module. Except for the different measurement and processing modules, the external interfaces of the probes are exactly the same. The probes are very convenient and simple to use, no need to set up, and can be used immediately after being connected. To adapt to different borehole diameter applications, the probes are available in Φ40 or Φ50 specifications. The probes can measure more than 20 parameters, including electricity, magnetism, density, radioactivity, borehole spatial orientation, temperature, pressure, flow, sound velocity, etc. Whether it is metal mines, coal fields, oil fields, radioactive mines, salt wells, or hydrological wells, they can be adapted for use. The parameters of conventional probes meet international standards.

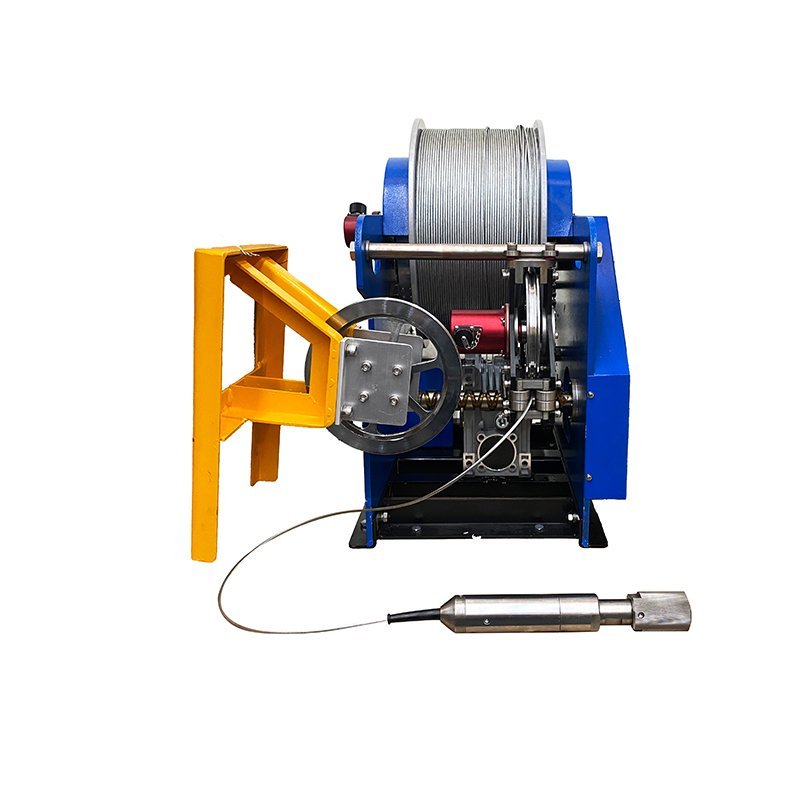

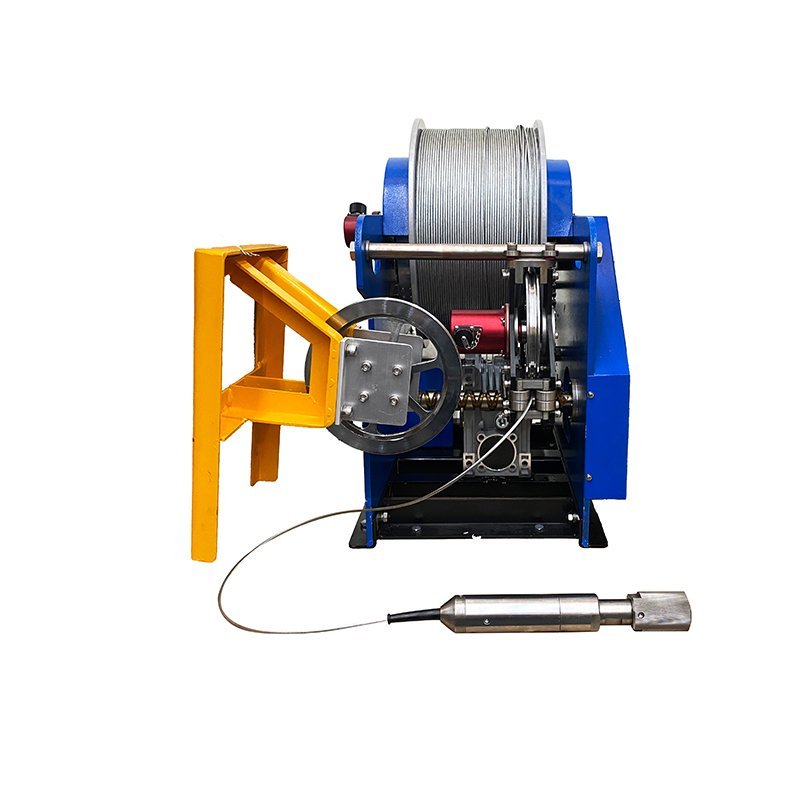

3. Winch and cable

The winch equipped with the PSK-2 CNC Logging System is currently the lightest electric logging winch. The winch is made of high-strength aluminum alloy. It has significant features such as non-magnetic, low sensitivity, light weight and durability. The winch works with stepless speed change and has a very reliable anti-slip function, manual function, and fully automatic tight cable arrangement function. Logging cables can be selected according to the equipment required by the user, ranging from armored single core to rubber multi-core, and from coaxial to multi-core spiral wires.

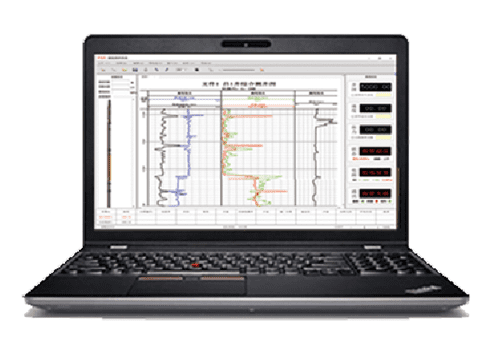

4. Software and PC

The software of the PSK-2 CNC Logging System is a visualization software running under Windows. The software consists of modules such as acquisition processing, scale calibration, curve editing, analysis filtering, etc. The functions are very powerful and the required PC configuration is not very high. The result data can be stored in a database for management or as a single data file for management. It can be exported to a format readable by software such as Sufer. Graphic results can be drawn using various printers, thermal plotters and other devices.

Applications

Applications

● Oil exploration: In oil exploration, it is used to measure the physical properties of underground rocks, such as density, resistivity, and sound velocity, to help determine the presence and distribution of oil and gas.

● Coalfield geological exploration: In coalfield geological exploration, it is used to measure the thickness, structure, and quality of coal seams, providing important data for the development of coal resources.

● Engineering logging: In engineering logging, it is used to measure the structure and integrity of the wellbore, detect damage and cracks in the well wall, and ensure the safety and stability of the wellbore.

● Perforation: In perforation operations, it is used to determine the location and depth of perforations, optimize perforation plans, and improve the development efficiency of oil and gas fields.

Detail Applications

Detail Applications

Different equipment combination application solutions can be adopted for different industry application scenarios.

● Coalfield logging system

Sound velocity and amplitude probe

Well inclination and natural potential combination probe

Digital electrode system probe

Well temperature and well fluid resistivity probe

Electromagnetic flow probe

Freezing hole measurement

● Hydrological logging system

Digital electrode system probe

Well temperature and well fluid resistivity probe

Inclinometer probe

Electromagnetic flow probe

Well caliper probe

Water level monitor

● Oilfield production CNC logging system

Isotope five-parameter combination logging tool

Output profile five-parameter combination logging tool

Multi-arm caliper tool

Acoustic variable density logging tool

Polarizability tool

● Metallurgical logging system

Gyro inclinometer

High-precision magnetic three-component logging instrument

Magnetic susceptibility meter

Digital electrode system probe

● Geotechnical engineering

High-precision inclinometer

Well caliper

Sediment meter

Displacement inclinometer Settlement displacement inclinometer

Description

Description

PSK-2 CNC Logging System integrated digital control logging system is a new generation of digital logging equipment., which based on summarizing more than 20 years in production and successful experience of digital logging equipment’s research and development, following the international new trend of development of the small digital logging technology. This set of equipment has the following advantages over other similar products:

- The measurement parameters are large and the scope is wide.

- The reliability is high and the Mean Time Between Failure (MTBF) is long.

- Portable, convenient for mobile transportation.

- Operating and maintenance is simple.

The main reason for these advantages is that the design and development is absorbing other’s merits, fully considering the variouts needs of the industry, and considering the competitiveness in the international market. PSK-2 can measure than 20 kinds parameters, covered with metal ore, coal, oil field, radioactive, hydrology, and other areas of the various user’s requirements, with great cost-effective.

Specifications

Specifications

| Part Name | URL Link |

| Ground integrated host | |

| Probes | |

| Winch and cable | |

| Software and PC |

Product images

Product images

1.Ground integrated host

2.Probes

3. Winch and cable

4. Software and PC

PS:For more useful information, please visit https://geotechcn.net/

FAQ

① In SI, it is m·s-2, and one percent of it is the international unit abbreviation g.u.;

② Conversion between SI and CGS: 1g.u.=10-1 mGal

Gravitational field: The space around the earth with gravity is called the gravitational field.

Gravitational potential: The gravitational potential W in the gravitational field is equal to the work done by a particle of unit mass moving from infinity to that point.

① The normal gravity field of the earth: Assuming that the earth is a rotating ellipsoid (reference plane), the surface is glossy, the internal density is uniform, or it is distributed in concentric layers, the density of each layer is uniform, and the deviation of the shape of the ellipsoid from the geoid is very small, then the gravity field generated by the earth is the normal gravity field.

② The normal gravity value is only related to the latitude, the smallest at the equator and the largest at the poles, with a difference of about 50,000 g.u.; the rate of change of the normal gravity value with latitude is the largest at 45° latitude, and zero at the equator and the poles; the normal gravity value decreases with increasing altitude, and its rate of change is -3.086 g.u.. The main feature of the long-term change is the "westward drift" of the geomagnetic elements, both the dipole field and the non-dipole field drift westward, and have a global nature.

The gravitational field strength is equal to the gravitational acceleration in both numerical and dimensional terms, and the two are in the same direction. In gravity exploration, all references to gravity refer to gravitational acceleration. The gravitational field strength at a point in space is equal to the gravitational acceleration at that point.

Gravity exploration is an exploration method that is based on the density difference of rocks and ores. Since density difference will cause local changes in the normal gravity field of the earth (i.e. gravity anomaly), it is used to solve geological problems by observing and studying gravity anomalies.

-1.png)