Welcome to Geotech!

Shallow Cavity Investigation In Limestone Quarry Working Face

- Solutions, Electromagnetic Solutions

- 31 views

Description

Electrical Instrument Solution:Shallow Cavity Investigation In Limestone Quarry Working Face

Ⅰ.Brief description of program

Shallow holes discovered in limestone mines may lead to heavy vehicle engineering accidents due to the collapse of limestone pits.

The application of 2D resistivity imaging with contact electrode was previously successful to determined shallow cavity in limestone mine. Then a new technique with ERT resistivity equipment, 3D resistivity measurement with S-Shape electrode configuration was attempted to locate shallow cavities within limestone layer which may display in more detail feature than previous 2D resistivity imaging result.

ERT resistivity method is successful in developing data collection as 3D s -shape resistivity system that can show mapping shallow cavity in detail scale for the purpose of future safety management and prevent possible occur an accident in mining activity.

Ⅱ.Project profile

1、Objectives

The application of 3D S-Shape resistivity measurement is to figure in detail scale the shallow cavity at face limestone mine that may help to manage mining activity in safe from sinkhole accidence by heavy vehicle working.

2、Location of survey area

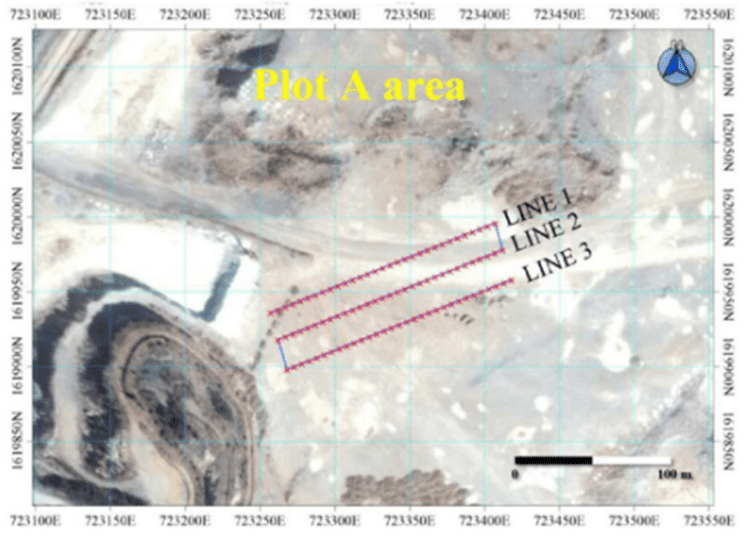

The survey area is located at limestone mine face of Siam City Cement Public Company Limited. The position of the mine displays faraway from Saraburi city around 20 km to the East where found in the topographic map sheet no. 5238 III (Amphoe Muak Lak) SERIES L7018. The boundary of the study area (Plot A and Plot B) covers of 722000E to 722350E, and 1619500N to 1625000N (Figure 1).

3、Topography of survey area

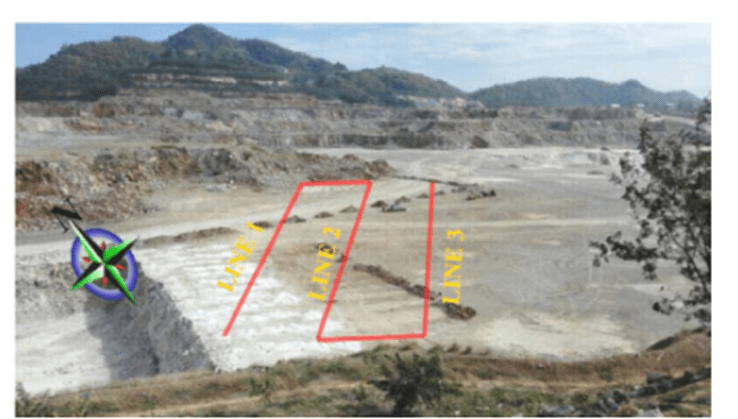

Both survey sides, Plot A and Plot B, are located in limestone mine with the elevation of the survey area is around 220-250 m (above mean sea level). Landscape of ground surface at the surveying displays as flat area by filled the basement with crushed stone. (Figure 2)

Ⅲ.3D S-Shape resistivity technique

Electrode configuration of 3D S-shape is linked for all survey lines (involving in taking measurement) to become in one connection system by connecting the end electrode to the next electrode of alongside survey line. Resistivity values having to collect in a complete 3D resistivity data set, should be performed in all possible direction.

Ⅳ.Results Show

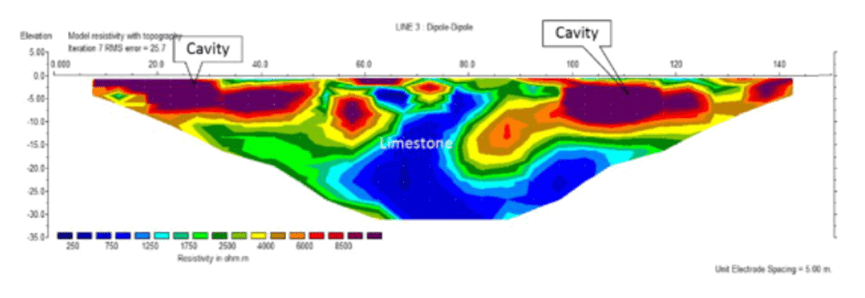

Resistivity value data obtained from 3D-S-Shape technique, could be presented as 2D section and 3D cube picture. As reading system, both data from Dipole-Dipole and Schlumberger array to create the 3D model to locate shallow cavity boundary.

As conceptual interpretation, cavity and limestone regions can be classified due to the different in resistivity value as follows.

(1)Shallow empty (air) cavity zone identified by Very high resistivity value (>5000 Ω•m).

(2)Surround country rock (Limestone) with different texture and dense of rock layer indicated by Vary resistivity value (generally 100-2000 Ω•m).

Compare the result showing Cavity zone (very high resistivity – red color) found in 2D resistivity section where data obtain from Dipole-Dipole and Schlumberger electrode array reading in Figure 15 and 16 for Plot A area. and Figure 25 and 26 for Plot B Area, respectively.

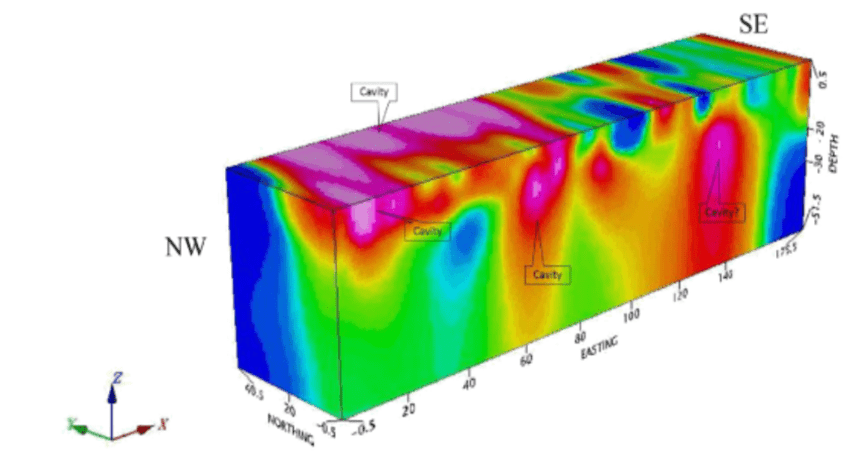

With data processing, 3D inversion models were created and interpreted cavity zones (from very high resistivity – Red color) into three cases as follows. The test results using electrical method of geophysical exploration are as follows.

(1)Pseudo 3D models obtain from three lines of 2D sections use both Dipole-Dipole and Schlumberger array as shown in Figure for Plot A area. and Figure for Plot B Area. Then 3D cube models are further displayed with limit very high resistivity zone (present as Cavity zone) as shown in Figure for Plot A area. and Figure for Plot B Area.

(2)3D S-shape model with Dipole-Dipole array as shown in Figure for Plot A area. and Figure for Plot B Area. Then 3D cube models are further displayed with limit very high resistivity zone (present as Cavity zone) as shown in Figure for Plot A area. and Figure for Plot B Area.

(3)3D S-shape model with Schlumberger array as shown in Figure for Plot A area. and Figure for Plot B Area. Then 3D cube models are further displayed with limit very high resistivity zone (present as Cavity zone) as shown in Figure for Plot A area.

Cavity zone (very high resistivity – red color) found in 3D resistivity Model from S-shape of Plot B area, data obtain from Schlumberger electrode array reading.

Ⅴ.Conclusion

3D S-shape resistivity measurement is successful to apply for locating the boundary of cavity in limestone (particularly at the mine face location). The results also show 2D sections on each survey line which obtain from 3D measuring. The presentation of 3D inversion models can be achieved in 3 types i.e.

(1)Pseudo 3D model from both Dipole-Dipole and Schlumberger, processed from 2D section of each survey line.

(2)3D S-shape of Dipole-Dipole array.

(3)3D S-shape of Schlumberger array.

Where all these outputs display in some differences of resolution, depth and pattern.

To compare 3D models from same location of Plot A.

3D S-shape model with Dipole-Dipole configuration reading displays three cavity zones with dimension of 20 m long x 25 m wide x 15 m thick, 20 m long x 15 m wide x 15 m thick and 20 m long x 20 m wide x 2 m thick. While 3D S-shape model with Schlumberger configuration reading can show only two main shallow cavity zones with dimension of 25-40 m long x 30-40 m wide x and 10-15 m thick and 40 m long x 30-40 m wide x 15-20 m thick.

FAQ

The double tap has a large current and can be used for IP testing to get more accurate data.

High-density apparent resistivity method is an array prospecting method, also known as automatic apparent resistivity system, which is developed from direct current method. Its function is equivalent to the combination of quadrupole sounding and electrical profiling method. The artificial electric field is formed by supplying electricity to the underground through electrodes. The distribution of the electric field is closely related to the distribution of the resistivity of the underground rock and soil medium. By measuring the artificial electric field at different parts of the surface, the distribution of the apparent resistivity of the underground medium is understood, and the underground geological structure is inferred and interpreted based on the distribution of the apparent resistivity of the rock and soil medium.

The principle of high-density electrical method is the same as that of traditional resistivity method. It is a combination method of multiple devices and multiple pole distances that integrates electrical depth sounding and electrical profiling method, which can obtain the conductivity characteristics of two-dimensional underground media. It has the characteristics of multi-device data acquisition in one pole arrangement, and highlighting abnormal information by obtaining ratio parameters, which greatly increases the amount of collected data, improves work efficiency, and ensures the accuracy and reliability of the pole running process.

This method is particularly sensitive to the water content of the surrounding rock. If the surrounding rock is broken and contains water, its apparent resistivity is significantly reduced. The apparent resistivity of intact and hard rock and soil is significantly higher than that of the surrounding rock in the fault zone or broken zone and water-rich zone. This method has a clear principle and intuitive images. It is a geophysical method with high resolution. In recent years, with the improvement of computer data acquisition technology, the exploration efficiency has been greatly improved, the coverage area and detection depth of the profile have been increased, reliable data can be obtained in a strong interference environment, the signal-to-noise ratio has been greatly improved, and the geological body can be accurately detected. This method has been widely and successfully applied in engineering and hydrogeological exploration and exploration of mineral and water resources.

(1) Application in coalfield and mine goaf detection

(2) Non-destructive detection of termite nests in dam foundations

(3) Karst and foundation surveys of railways, roads and tunnels

(4) Delineation of stratum lithology boundaries

(5) Survey of the leakage range of landfills

(6) Ancient tomb surveys

(7) Detection of sewage pipes

(8) Non-destructive testing of leakage in reservoirs and river dams

(9) Detection of bedrock fracture zones

(10) Soil salinity and water quality surveys

(11) Detection of ancient tunnels, air-raid shelters, metal burial sites, etc.

(1)The high-density resistivity method is based on the resistivity method, so it is suitable for all underground explorations with obvious conductivity differences;

(2)Any medium underground will have a weak polarization potential at the moment of power on and off, which will affect our measurement of the true potential difference. When the electrode distance is small, the loop current is large, which has little effect on the measurement results; when the electrode distance is too large, the interference potential is close to the effective potential, which has a greater impact on the measurement results. Therefore, due to the influence of the power supply electrode distance, the exploration depth cannot be too large, generally within 100m. When the conductivity of the soil medium is good, it can be appropriately increased, and the exploration depth in the soil medium with poor conductivity is appropriately smaller;

(3)It is generally less used in cities, near large transmission lines, etc. due to site restrictions and industrial stray current interference; 4. In areas such as concrete pavements and exposed bedrock surfaces, it is also less used due to the difficulty of electrode layout.

-1.png)